Reciprocating Air Compressors

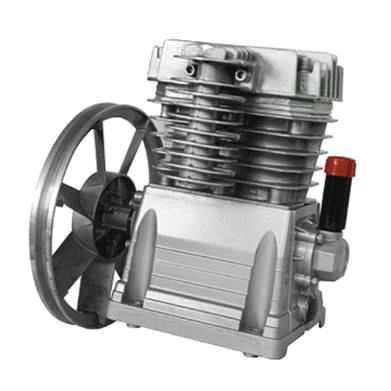

Reciprocating air compressors are positive displacement machines, meaning that they increase the pressure of the air by reducing its volume. This means they are taking Description: (SY-L260) Reciprocating Air Compressor Head Sectionin successive volumes of air which is confined within a closed space and elevating this air to a higher pressure. The reciprocating air compressor accomplishes this by a piston within a cylinder as the compressing and displacing element.

Single-stage and two-stage reciprocating compressors are commercially available.

Single-stage compressors are generally used for pressures in the range of 70 psig to 100 psig. Two-stage compressors are generally used for higher pressures in the range of 100 psig to 250 psig.

Note that:

- 1 HP ~ 4 CFM at 100 psi

and that 1 to 50 HP are typically for reciprocating units. Compressors 100 hp and above are typically Rotary Screw or Centrifugal Compressors.

The reciprocating air compressor is single acting when the compressing is accomplished using only one side of the piston. A compressor using both sides of the piston is considered double acting.

Load reduction is achieved by unloading individual cylinders. Typically this is accomplished by throttling the suction pressure to the cylinder or bypassing air either within or outside the compressor. Capacity control is achieved by varying speed in engine-driven units through fuel flow control.

Reciprocating air compressors are available either as air-cooled or water-cooled in lubricated and non-lubricated configurations and provide a wide range of pressure and capacity selections.