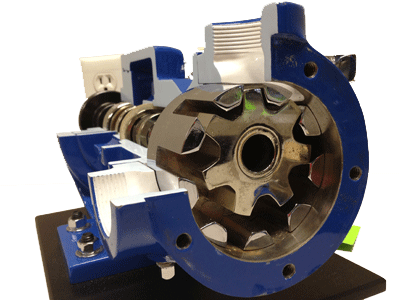

Gear Pumps

As the gears rotate they separate on the intake side of the pump, creating a void and suction which is filled by fluid. The fluid is carried by the gears to the discharge side of the pump, where the meshing of the gears displaces the fluid. The mechanical clearances are small— in the order of 10 μm. The tight clearances, along with the speed of rotation, effectively prevent the fluid from leaking backwards.

The rigid design of the gears and houses allow for very high pressures and the ability to pump highly viscous fluids.

Many variations exist, including; helical and herringbone gear sets (instead of spur gears), lobe shaped rotors similar to Roots Blowers (commonly used as superchargers), and mechanical designs that allow the stacking of pumps.

Suction and pressure ports need to interface where the gears mesh. Some internal gear pumps have an additional, crescent shaped seal.

Pump formulas:

- Flow rate in US gal/min = Displacement X rpm/231 (displacement in in3/revolution)

- Power in hp = US gal/min X (lbf/in³)/1714

Generally used in:

- PETROCHEMICALS: Pure or filled bitumen, pitch, diesel oil, crude oil, lube oil etc

- CHEMICALS: Sodium silicate, acids, plastics, mixed chemicals, isocyanates etc

- PAINT & INK

- RESINS & ADHESIVES

- PULP & PAPER: acid, soap, lye, black liquor, kaolin, lime, latex, sludge etc

GISP Ltd. can supply a variety of most reliable and well-known brands of gear pumps for different usage such as

- Viking Pump

- GRUNDFOS

- Johnson Pump

- Parker

- Haight Pump

- Eaton